What Are The Causes Of Cracking Of Steel Castings?

2024/04/29

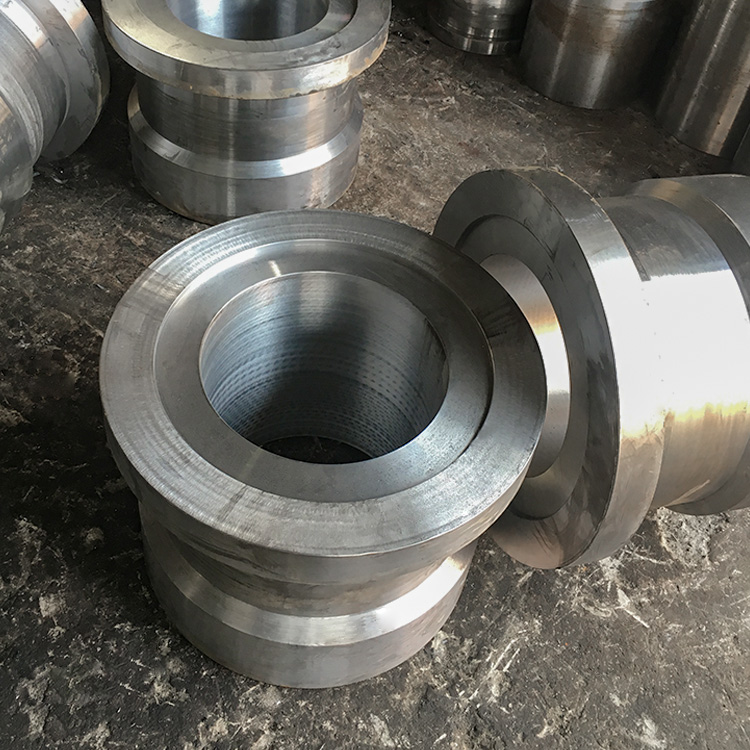

The products cast by steel casting manufacturers usually have pores, sand holes, shrinkage, cracks and other defects, and the common hot crack defects in cracks, so what are the main reasons for the cracking of steel casting parts?

When casting steel parts, due to certain reasons, such as: The temperature is not uniform, the casting is not consistent, so the steel casting products in the process of processing, will soon appear cracking situation, especially for some people who have just entered the casting industry, see the cracking situation is very different, most of them will have doubts, then let the Quansheng mechanical steel casting engineers to summarize some common steel casting cracking reasons:

1, the strength of the casting when the steel casting molding is not up to standard, for the slender core, the staff needs to pay attention when filling, because if the casting is distorted, it will lead to the product can not be released smoothly.

2, the direction of the molded casting surface demoulding will have obvious lateral pits, because the molded part demoulding inclination is relatively small, so that the surface of the casting grinding degree is not sufficient, so the demoulding resistance will be amplified, if it is a die-casting part, it will tear under a particularly large demoulding resistance.

3. For those steel casting products whose wall thickness is not uniform enough, the place where the thin wall meets the thick wall and the place where the turning point is formed and contracted will be easily hindered.

4. The alloy impurity composition in the casting of steel parts manufacturers is too high, which will directly reduce the plasticity of the alloy itself, especially when the iron content is too high or the silicon content is too low.

5. The temperature of the mold used in casting and the pouring temperature are low, so it will be easy to fill the phenomenon of poor, and the matrix of the metal can not be integrated completely, if the strength of the solidification is not enough, it will be easy to crack, especially the location of the gate within the distance.

When the shrinkage of the cast steel is not hindered by anything, then the dendrite skeleton can shrink freely. When the contraction of dendrite skeleton is hindered by sand mold, it will not be able to shrink freely and produce the corresponding tensile stress. At this time, when the tensile stress exceeds the limit of the strength of the material, there will be cracking between the dendrites, resulting in hot cracks in the product.